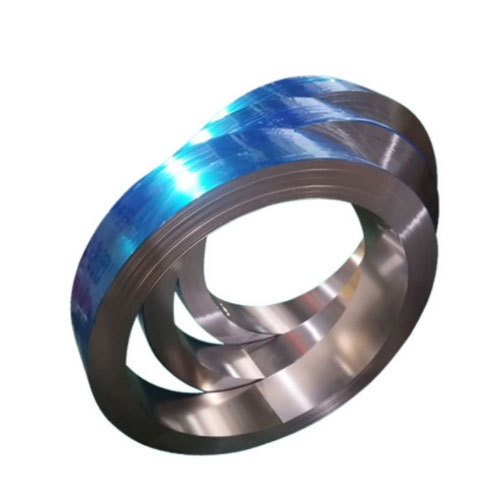

201 Stainless Steel Strip 2.8mm

- Information

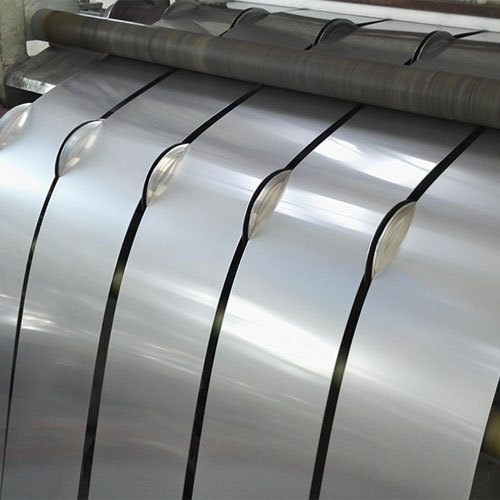

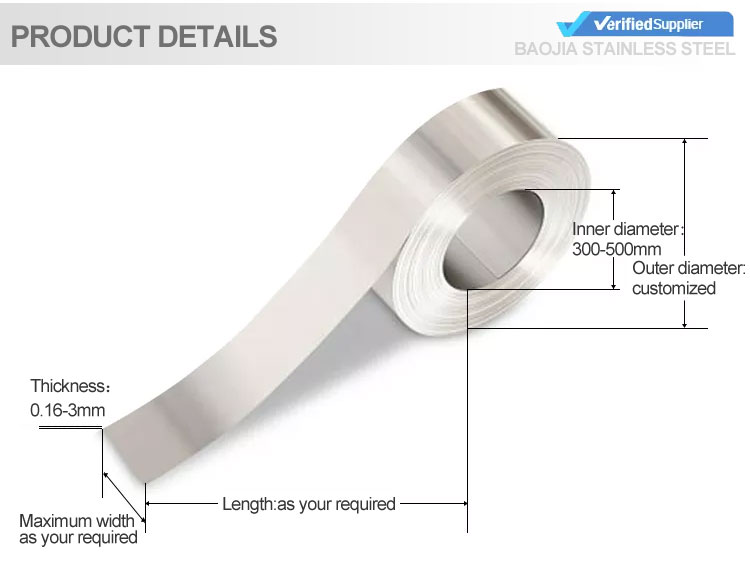

- Product Description

201 Stainless Steel Strip 2.8mm

| Stainless Steel Coil Strip | |||||||||||

| Technique | Surface Finish | Grade Series | Thickness(mm) | Width(mm) | Application | ||||||

| Main Dimension | |||||||||||

| 20-800 | 1000 | 1219 | 1240 | 1250 | 1500 | Petro-chemical industry,Tanks Construction material | |||||

| Hot Rolled | No.1 / 2E | 201/202/ | 2.2-12.0 | √ | √ | √ | √ | √ | |||

| 304 | |||||||||||

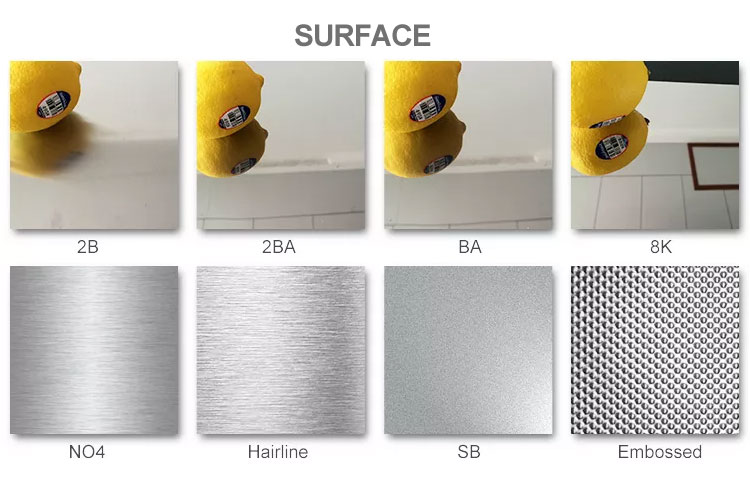

| Cold Rolled | 2B | 201/304 | 0.25-3.0 | √ | √ | √ | √ | √ | √ | ||

| 410S/430 | 0.16-3.0 | √ | √ | √ | √ | ||||||

| No.4 / Hairline | 201/304 | 0.22-3.0 | √ | √ | √ | √ | √ | ||||

| Mirror / Linen | |||||||||||

| SB | 410S/430 | 0.16-3.0 | √ | √ | √ | √ | √ | ||||

| BA | 201/304 | 0.2--1.8 | √ | √ | √ | √ | |||||

| 410S/430 | 0.16-3.0 | √ | √ | √ | √ | ||||||

| 2BA | √ | √ | √ | √ | |||||||

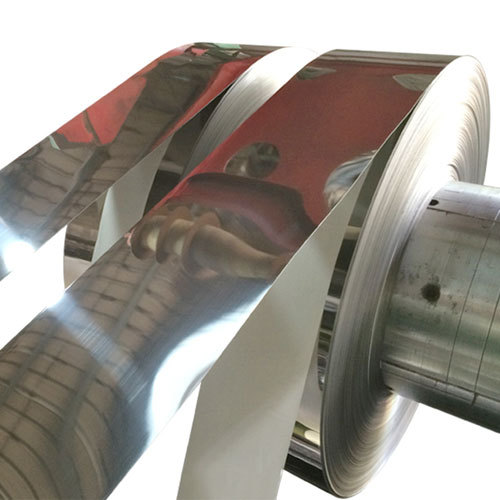

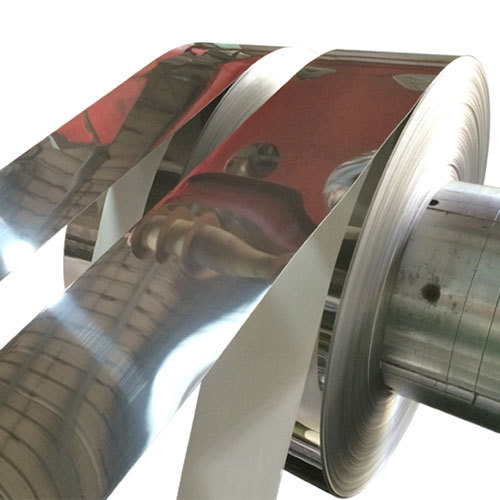

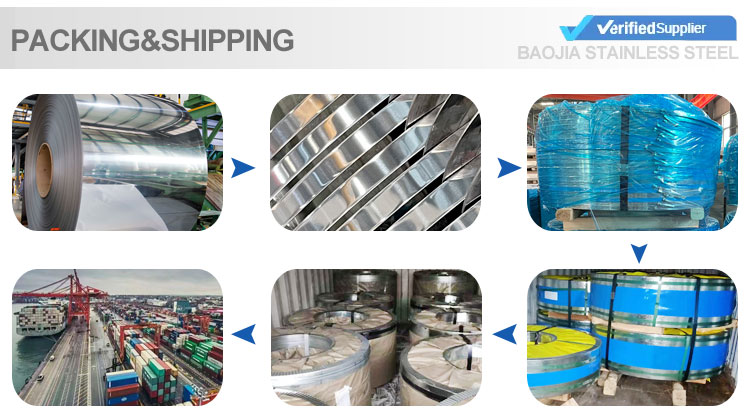

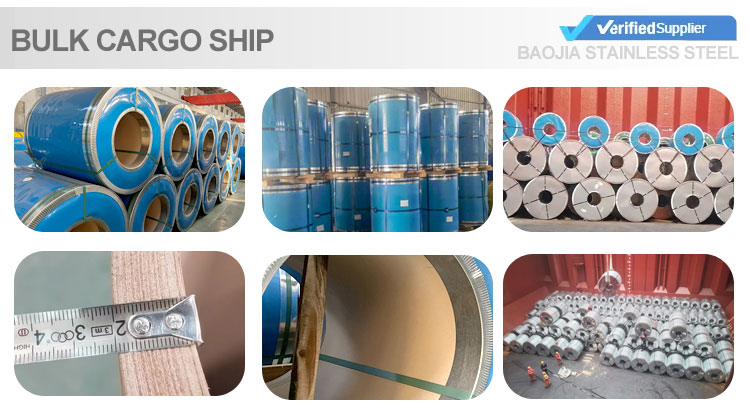

Stainless steel strip packaging and loading

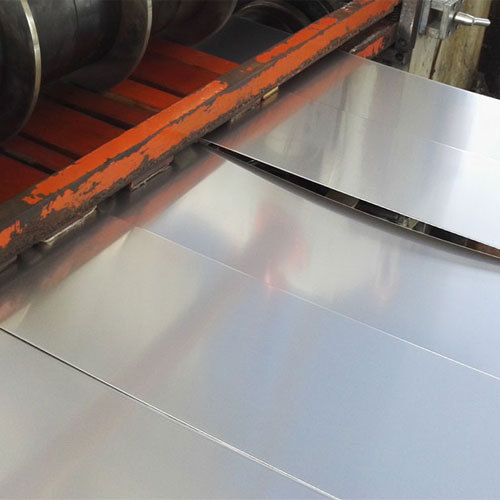

1. Stainless steel strip covered with wooden plate for protection in transportaiton.

2. All stainless steel strip will be loaded in strong wooden packages.

3. Every cartons loaded with good shoriong and container.

4. Transportation speed is quick. And keep customer each informed.

BA / NO.4 NO.3/ hair line with PVC, BAOJIA support to use 2-3CM inner paper core, try best to make sure taht coils won't collapse.

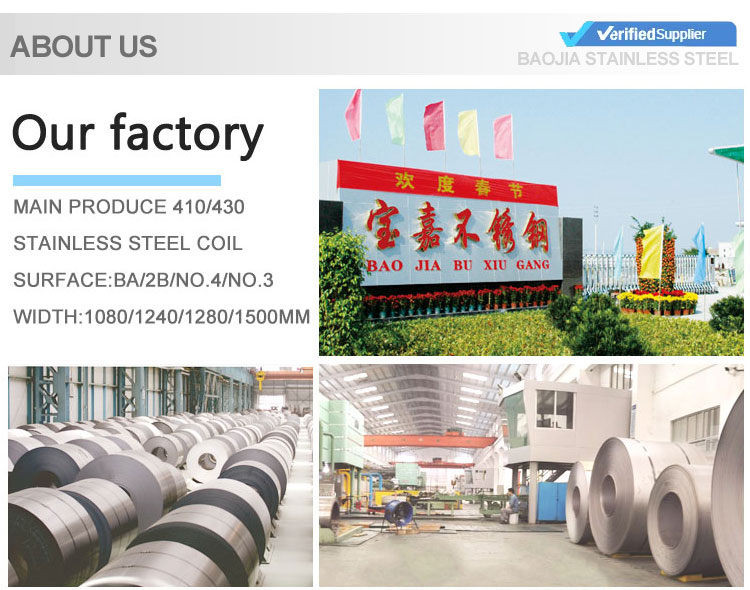

Our Manufacturing Department:

1. Cold rolling machines, 20Hi / 18Hi roller with computer control system

2. 18 & 20 oil roller rolling machine, makes the surface more smooth & steady, 0.01mm tolerance in thickness

3. Bright anneal Oven 1050mm, two lines, 1450mm one line

4. Bright process machine, with paper interleave during processing, protect the surface

5. Strip coil cutting, slit/trim edge cutting machines

6. 2B, BA finshed surface of 410s, soft DDQ quality

Main Products: Cold rolled Stainless steel coil, Stainless steel circle, Stainless steel sheet, Stainless steel strip, Stainless steel 430, 410, 409, 201grade.

We can customize the exclusive brand with the smallest MOQ for customer.

We warmly wecome customers from all over the world. And look forward to establishing a long -trem mutual beneficial relationship for a bright future together. Guang dong baojia stainless steel will always be your reliable partner in china.

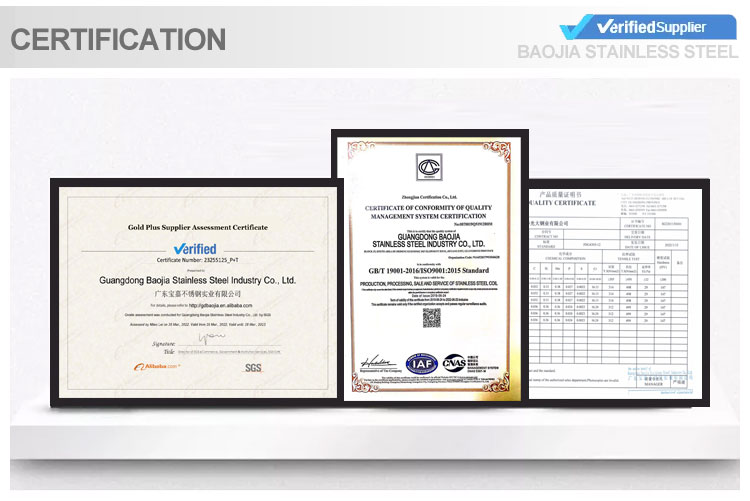

We can provide you neccessory certificates for your custom prupose.

1. Mill test certificate

2. CO/Form A/Form E/Form F

3. PSC/CIQ

Special Request of other certificate,Pllease check with us.

Q1: Are You Factory or Trader? |

A1: BaoJia is the largest manufacturer of cold rolled stainless steel material in Jieyang, and more than 20 years of history in the stainless steel industry. Almost everyone know us. |

Q2: Which Material You Can Provide? |

A2: 430 Stainless Steel, 410S Stainless Steel, 409L Stainless Steel, 201 Stainless Steel. |

Q3: Which HR Material You Use? |

410 - TISCO,JISCO,LIANZHONG 430 - BAOSTEEL, TISCO, JISCO,LIANZHONG 201 - BAOSTEEL, DINXING |

Q4: Can You Provide Mill Test Certificate? |

A4: YES! Mill Test Certificate for both hot rolled raw material coils and cold rolled coils are available. |

Q5: How To Get A Sample? |

A5: FREE samples are available for your checking and testing. You need to send us your detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side. |

Q6: How To Visit Your Factory? |

A6: Most of the main cities have flight to Jieyang; you can take flight to Jieyang Chaoshan International Airport. If you come from Guangzhou, it will take 1 hour by flight (every day 5 flights), or 6 hours by bus. If you come from Shanghai, it will take 2 hours by flight (every day 5 flights). If you come from Yiwu or Ningbo, it will take about 1.5 hours by flight. If you come from Hongkong, it will take 1 hour by flight (every day 1 flight around noon time). |

Hot rolled pickled plate (coil): EAF--VOD/AOD+LF (Use ESR when the requirements are higher)--Continuous casting CC--Slab heating--Descale -Rough rolling (hot) - Finish rolling (hot) - Annealing - Pickling 2) Cold rolled plate (coil): Hot-rolled pickled steel coil-cold rolled-annealing-pickling-(polishing)